Subtotal $0.00

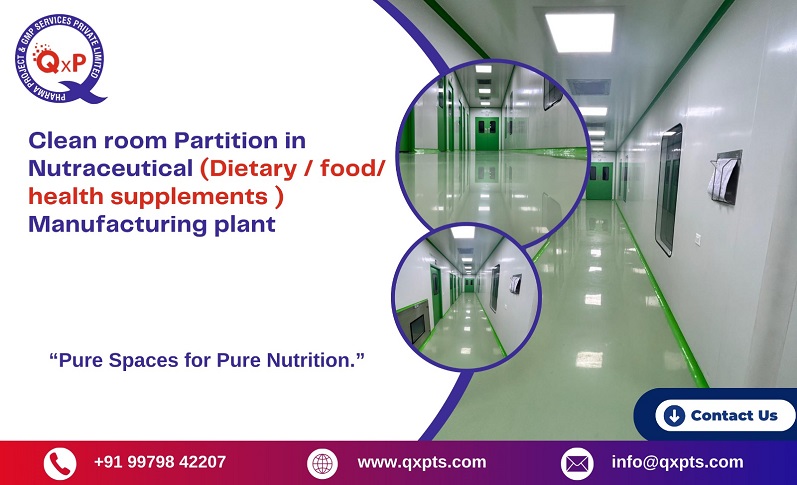

Designing Efficient Clean Room Partition in Nutraceutical Manufacturing: QxP Pharma Consultant and GMP Services

Clean room Partition in Nutraceutical Manufacturing Plant is crucial for maintaining hygiene, contamination control, and regulatory compliance. QxP Pharma Consultant and GMP Services, a trusted GMP Services Provider in India, specializes in designing and implementing efficient clean room solutions. As a leading Pharma Consultant in India, QxP Pharma Consultant in India ensures that every Clean Room Partition in Nutraceutical Manufacturing Plant meets stringent quality standards, promoting safety, efficiency, and compliance in pharmaceutical production.

Importance of Clean Room Partitions in Nutraceutical Manufacturing

Nutraceutical products are consumed daily by millions of people, making hygiene and safety non-negotiable. Clean room partitions help in creating segregated, controlled zones that reduce contamination risks from dust, microbes, personnel movement, and external environmental factors.

Key benefits include:

- Controlled air pressure and airflow management

- Prevention of cross-contamination between processes

- Compliance with GMP, FSSAI, and international quality standards

- Enhanced cleaning, sanitization, and maintenance efficiency

- Improved operational workflow and process control

Clean room partitions form the backbone of a compliant nutraceutical manufacturing plant, especially for dosage forms such as tablets, capsules, powders, liquids, and sachets.

Types of Clean Room Partition Systems Used in Nutraceutical Plants

Different nutraceutical processes require tailored partition solutions. Commonly used clean room partition systems include:

- Modular PUF Panel Partitions: Lightweight, durable, and thermally insulated

- GI / PPGI Panel Partitions: Cost-effective and corrosion-resistant

- Glass or View Panel Partitions: Improved visibility and monitoring

- HPL (High Pressure Laminate) Panels: Easy to clean and highly durable

These systems are designed to integrate seamlessly with HVAC, electrical, and utility services while maintaining GMP-compliant finishes.

QxP Pharma Consultant and GMP Services

QxP Pharma Consultant and GMP Services offer end-to-end expertise in designing and implementing clean room partition systems for nutraceutical manufacturing plants. With deep industry knowledge and hands-on execution experience, QxP ensures that every partition system aligns with global GMP guidelines and nutraceutical regulatory requirements.

Their services include:

- Clean room concept development and layout planning

- Selection of appropriate partition materials

- Integration with HVAC, utilities, and process flow

- GMP-compliant installation and execution

- Support during audits and regulatory inspections

QxP’s approach focuses on building facilities that are compliant, efficient, and future-ready.

QxP Pharma Consultant in India

As a trusted QxP Pharma Consultant in India, the organization understands the unique regulatory landscape governing nutraceutical and dietary supplement manufacturing. Indian facilities must comply with FSSAI regulations while also meeting international GMP expectations for export markets.

QxP provides localized solutions that address:

- Indian regulatory requirements

- Cost-effective yet compliant infrastructure design

- Adaptability for both domestic and global markets

- Smooth coordination with multiple project stakeholders

This makes QxP a preferred partner for nutraceutical startups as well as established manufacturers across India.

GMP Services Provider in India

A reliable GMP Services Provider in India plays a crucial role in ensuring that clean room partition systems meet quality, safety, and compliance benchmarks. GMP compliance is not limited to documentation—it begins with proper facility design.

QxP Pharma Consultant delivers comprehensive GMP services including:

- Facility and clean room qualification support

- SOP and documentation alignment

- Risk assessment and contamination control strategies

- Audit readiness and compliance gap analysis

By aligning clean room partitions with GMP expectations, manufacturers can avoid costly redesigns and regulatory delays.

Pharma Consultant in India

An experienced Pharma Consultant in India brings cross-industry expertise that benefits nutraceutical manufacturers aiming for pharmaceutical-grade quality standards. Clean room partition systems designed with pharmaceutical precision offer higher assurance of product safety and brand credibility.

QxP Pharma Consultant bridges the gap between pharma-grade compliance and nutraceutical manufacturing practicality, ensuring robust infrastructure without unnecessary complexity.

Conclusion:

Clean room partition systems are a critical investment for nutraceutical manufacturing plants producing dietary supplements, functional foods, and health products. They directly impact hygiene, compliance, operational efficiency, and product quality.

With expert guidance from QxP Pharma Consultant and GMP Services, manufacturers can develop clean room infrastructure that meets current regulations, supports future growth, and ensures consumer trust. As a leading QxP Pharma Consultant in India, GMP Services Provider in India, and trusted Pharma Consultant in India, QxP delivers compliant, cost-effective, and future-ready clean room partition solutions for the nutraceutical industry.